Copper Nickel

Copper Nickel (Cu-Ni) alloys have a remarkable combination of good resistance to both corrosion and biofouling in seawater. As they are also readily welded and fabricated, they are an obvious choice for pipe systems, heat exchangers and structures engineered for marine use. Copper Nickels have been specified for seawater use for over 50 years; they are the materials of first choice for seawater pipework and have successfully used in:

• Merchant and military shipbuilding

• Offshore oil and gas installations

• Coastal petroleum and petrochemical processing plants

• Seawater desalination plants

• Coastal electricity generation plants

There are two main grades of Copper Nickel (Cu-Ni) alloy used in marine service : 90/10 (10% nickel) and 70/30 (30% nickel). The 70/30 alloy is stronger and has greater resistance to seawater flow; but 90/10 will provide good service for most applications and, being less expensive, tends to be more widely used.

Despite the rough conditions in marine service and the highly corrosive nature of seawater, the copper nickel alloys provide well balanced combination of technical and economical advantages

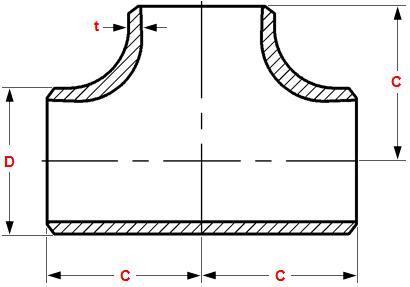

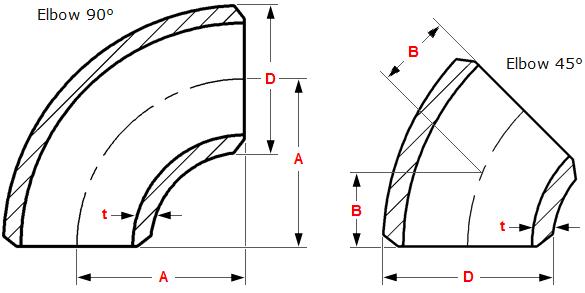

Products

Standard Specifications for Copper Nickel Cu-Ni 90/10

| Elements | UNS C70600 | DIN 176642.0872 | DIN 860192.1972 | BS 2871CN 102 | EEMUA 234UNS C7060X | ASTM B466C70600 | JIS H3300C7060T |

| Ni% | 9-11 | 9-11 | 9-11 | 10-11 | 10-11 | 9-11 | 9-11 |

| Fe% | 1.0-1.8 | 1-2 | 1.5-1.8 | 1-2 | 1.5-2.0 | 1.0-1.8 | 1.0-1.8 |

| Mn% | max 1.0 | 0.5-1.0 | 0.5-1.0 | 0.5-1.0 | 0.5-1.0 | max 1.0 | 0.2-1.0 |

| C% | max 0.05 | max 0.05 | max 0.05 | max 0.05 | max 0.05 | max 0.05 | |

| Pb% | max 0.02 | max 0.03 | max 0.01 | max 0.01 | max 0.01 | max 0.02 | max 0.05 |

| S% | max 0.02 | max 0.02 | max 0.005 | max 0.05 | max 0.02 | max 0.02 | |

| P% | max 0.02 | max 0.02 | max 0.02 | max 0.02 | max 0.02 | ||

| Zn% | max 0.5 | max 0.5 | max 0.05 | max 0.20 | max 0.50 | max 0.50 | |

| other imp. | max 0.5 | max 0.3 | max 0.2 | max 0.3 | max 0.3 | ||

| Cu% | rem. | rem. | rem. | rem | rem | rem | rem |

Standard Specifications for Copper Nickel Cu-Ni 70/30

| Elements | UNS C71500 | DIN 17664 2.0882 | BS 2871 CN 107 | ASTM B466C71500 | JIS H3300C7150T |

| Ni% | 29-33 | 30-32 | 30-32 | 29-33 | 29-33 |

| Fe% | 0.4-1.0 | 0.4-1.0 | 0.4-1.0 | 0.4-1.0 | 0.4-1.0 |

| Mn% | max 1.0 | 0.5-1.5 | 0.5-1.5 | max 1.0 | 0.2-1.0 |

| C% | max 0.05 | max 0.05 | max 0.06 | max 0.05 | |

| Pb% | max 0.02 | max 0.03 | max 0.01 | max 0.02 | max 0.05 |

| S% | max 0.02 | max 0.02 | max 0.08 | max 0.02 | |

| P% | max 0.02 | max 0.02 | max 0.02 | ||

| Zn% | max 0.5 | max 0.50 | max 0.50 | max 0.50 | |

| other imp. | max 0.5 | max 0.3 | max 0.0 | ||

| Cu% | rem. | rem. | rem. | rem. | rem. |

Physical and Mechanical Properties

Copper Nickel (Cu-Ni) 70/30 and 90/10

| Physical PropertiesCopper Nickel | Cu-Ni 70/30 | Cu-Ni 90/10 |

| Density (20°C) g/cm3 | 8.95 | 8.94 |

| Specific heat (20°C) J/kg K | 377 | 377 |

| Melting Range (°C) | 1170-1240 | 1100-1145 |

| Thermal conductivity (20°C) W/m K | 29 | 50 |

| Coeff of linear exp. (20-100°C) 10-6/K | 16 | 17 |

| Electrical resistivity (20°C, annealed) microohm cm | 34 | 19 |

| Modulus of elasicity (20°C, annealed) kN/mm2 | 152 | 138 |