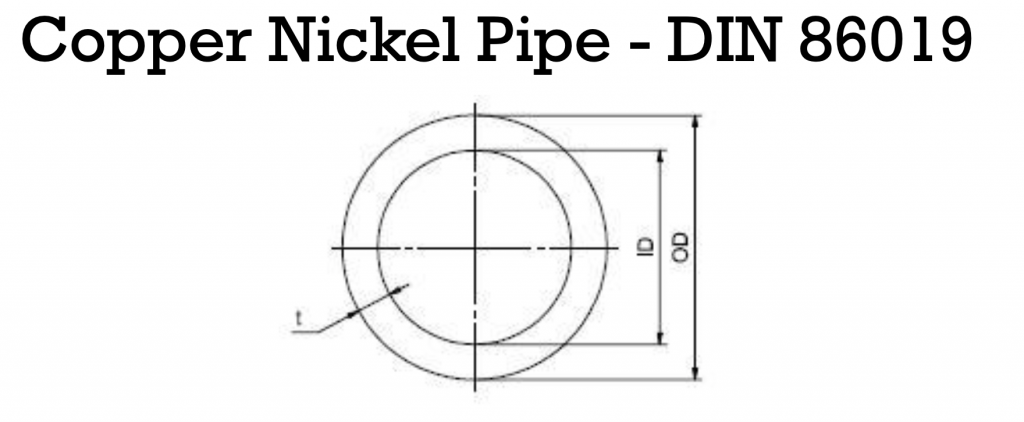

Copper Nickel Pipe – DIN 86019

DIN 86019 is an important standard for the shipbuilding and offshore industries, as copper-nickel alloy pipes are commonly used in these industries due to their excellent resistance to corrosion, biofouling, and erosion. The standard provides assurance that these pipes are manufactured to high standards and are suitable for use in demanding marine environments.

Copper Nickel Pipe – DIN 86019

| Material Cu-Ni 90/10 and Cu-Ni 70/30 | ||||||

| Diameter Size | DIN 86019 / DIN 1755 T3 / DIN 86018 / BS 2871 Part2 | |||||

| Nominal | Actual OD | 10 Bar | 14 Bar | |||

| Wall Thickness (mm), t | Theoretical Weight (Kg/M) | Wall Thickness (mm), t | Theoretical Weight (Kg/M) | |||

| Inch | mm | mm | ||||

| Seamless Pipe | ||||||

| 1/8 | 6 | 10 | 1 | 0.25 | – | – |

| 1/4 | 8 | 12 | 1 | 0.31 | – | – |

| 3/8 | 12 | 16 | 1 | 0.42 | 1.5 | 0.61 |

| 1/2 | 16 | 20 | 1 | 0.53 | 1.5 | 0.78 |

| 3/4 | 20 | 25 | 1.5 | 0.99 | 1.5 | 0.99 |

| 1 | 25 | 30 | 1.5 | 1.20 | 2 | 1.60 |

| 1 1/4 | 32 | 38 | 1.5 | 1.54 | 2 | 2.05 |

| 1 1/2 | 40 | 44.5 | 1.5 | 1.81 | 2 | 2.41 |

| 2 | 50 | 57 | 1.5 | 2.34 | 2 | 3.12 |

| 2 1/2 | 65 | 76 (76.1) | 2 | 4.16 | 2 | 4.16 |

| 3 | 80 | 88.9 (89) | 2 | 4.88 | 2.5 | 6.07 |

| 4 | 100 | 108 | 2.5 | 7.41 | 2.5 | 7.41 |

| 5 | 125 | 133 | 2.5 | 9.16 | 3 | 10.95 |

| 6 | 150 | 159 | 2.5 | 10.99 | 3 | 13.14 |

| 7 | 175 | 193.7 (194) | 2.5 | 13.43 | 3.5 | 18.70 |

| 8 | 200 | 219 (219.1) | 3 | 18.21 | 3.5 | 21.19 |